Stool designs. Assembling and decorating stools at home

If you decide to master the process of making home furniture, you should start with the simplest designs. First, try making a stool with your own hands. You can completely cope with this task even if you do not have any special skills in working with wood.

Drawing up a drawing

To avoid mistakes, it is worth making at least a schematic drawing of the future design. Our stool will consist of the following parts:Seats: its side can be equal to 350-430 mm;

Main details of the stool

Tsarg - bars under the seat, creating a solid foundation; it is to them that the legs are attached;

Legs (supports) with a height of 45-50 cm and a cross-section of 35-50 mm;

Legs that serve to give the structure additional stability; It is better to place them not exactly in the center of the legs, but a little closer to the bottom;

Crackers: corners made of wood or metal, mounted in the corners under the seat (we'll talk about them a little lower).

Simple DIY stool

Advice! A utility stool can be made small – up to 260-280 mm high with a seat size of 260x260 mm.

Required tools and materials

To work with wood we will need:Ready-made bars or dry board 200 mm wide (it will be more convenient to work with this size, it can be easily cut lengthwise into several 50 mm bars);

Roulette;

Square;

Fine-toothed hacksaw or power saw for cutting wood;

Rasp;

Chisel;

Drill or screwdriver: they not only fasten parts together, but also drill holes; you can replace it with a set of screwdrivers;

Self-tapping screws;

Sandpaper.

It’s great if you have a router available, with which you can quickly prepare the grooves and process the edges. Experienced craftsmen also use grinding machines - with wheels of different grain sizes. However, you can also use the usual old-fashioned method - select grooves and make tenons only with a chisel, jigsaw and rasp, and then sand the wood with sandpaper.

Grooving

Sawing and processing of parts

1. First, we need to get 4 pieces of equal size for legs, drawers and legs.2. To obtain a stable structure, the bars should be cut strictly at 90°.

3. When calculating the sizes of the drawers and legs, do not forget that you must add the length of the tenons to their length (see the figure below).

Marking the legs

4. Our design should not have chips or tears, otherwise during use it will be easy to catch a hangnail. Therefore, after cutting the parts, carefully process with sandpaper No. 40-60, wound for convenience on the block, edges and cuts of workpieces. It is also necessary to clean out obvious irregularities.

5. Using sandpaper with a finer abrasive No. 80-120, and then No. 160-320, we again go through the entire plane of each part twice.

How to choose a groove and make tenons?

1. Connection using self-tapping screws is very unreliable - the stool will become loose very quickly. Therefore, to attach the legs and drawers, we will use a tongue-and-groove connection.2. The simplest option is rectangular studs. Their width should be 1/3 of the thickness of the part, and their length should be about 80% of its thickness. That is, if the thickness of our leg is 20 mm, then we must make spike 16 mm long and 7 mm wide(multiply 20 by 1/3 and get 6.67 mm, round the figure to 7).

Rectangular tenon for connecting legs

3. So, we mark the location of the tenons on the drawers and legs.

Tongue-groove connection

4. Since it is much easier to fit a tenon than a groove, we start working with making grooves.

5. To drill them out, it is more convenient to use a drill or screwdriver. After making several holes (see photo), we select the excess wood between them with a very sharp chisel(with a blunt instrument you can only hurt yourself).

6. To make the walls even, you can attach a small block to the groove line - in this case, you can easily select a groove at 90°.

7. Of course, it is much easier to make tenons on a milling machine. But you can cut them out using the old-fashioned method of marking using the usual jigsaw and rasp, and if there is a jigsaw in the house, then things will go even faster.

8. Check the connection. It should be tight enough, and the tenon should fit into the groove tightly to the very end.

Assembling the stool

1. We assemble the legs in pairs, fastening them with drawers and legs. To check, first assemble the stool dry, without using glue. We check the accuracy of the dimensions of the parts and the correctness of their fit. We eliminate the identified shortcomings.

Checking the evenness of the parts in pairs

2. If there are no errors, disassemble the structure and drop a few drops into the holes of the grooves drops of glue, and then spread it on the walls with thin wood chips. After drying, you can additionally secure the connections with self-tapping screws.

3. To sitting It doesn’t warp quickly, it’s better to assemble it from several (5-7) boards up to 80 cm wide.

4. Glue the seat boards, coat them with glue on the sides, and tighten them clamps(tools for tightening and pressing parts tightly together).

We tighten the glued seat with clamps

5. Wait for the glue to dry completely.

6. Apply glue again, but on the back side of the seat, attach the seat to our stool, align the structure and press it tightly. We immediately remove excess glue.

7. In principle, the seat can be screwed or secured using wooden dowels (chops) 3 cm long.

8. To strengthen the back side of the seat, we attach small corners to the legs and drawers (they are called breadcrumbs) or use a furniture corner tie.

We attach corners (crackers) in the corners

Furniture tie for drawers

The structure can also be strengthened using ordinary bars attached to the inside of the stool in the drawer area

Plywood stool

You can make the simplest design from scraps of 3mm plywood for a summer house or garage in a couple of hours. Thinner sheets will quickly break under the weight of the human body. It is better to use birch plywood. It is easier to process, and products made from it are painted more evenly.There is no point in explaining the manufacturing process in detail - the figure below shows in detail the order of cutting and assembly. All workpieces are cut with a saw by hand or with a jigsaw and thoroughly cleaned. The finished product can be varnished after assembly.

The simplest plywood stool

Children's stool made of plywood

Video: How to make a folding stool

Despite the wide range of furniture in modern stores, some people prefer to make stools with their own hands. Thanks to this approach, you will be able to take into account the features of the interior, use really high-quality materials and decorate the product in your own way.

Features of the stool design

A modern stool is a very simple attribute of any kitchen. It’s not difficult to make such a product with your own hands, because there is many ready-made drawings and photographs that even a beginner can use to assemble. Plywood, waste wood and even finished timber are often used as the main material.

In essence, a classic stool consists of several elements that are securely fastened together. The product consists of the following parts:

- cover or base of the structure, which has a round or square shape;

- 4 identical legs made of wood;

- tsargi, that is, elements connecting all the legs of the stool;

- a seat with rounded edges or covered with thick fabric.

Purchased or homemade stool?

Some people prefer store furniture. This is due to its readiness for use. You don't have to make seats, buy materials and waste time. Just visit the store or look at catalogs on the Internet. However, you need to take into account that the photos of products posted on the site sometimes do not correspond to reality. So, there may be a discrepancy in sizes and shades. If you choose inexpensive stools at sales, you may encounter low-quality shaky construction and various defects.

Some people prefer store furniture. This is due to its readiness for use. You don't have to make seats, buy materials and waste time. Just visit the store or look at catalogs on the Internet. However, you need to take into account that the photos of products posted on the site sometimes do not correspond to reality. So, there may be a discrepancy in sizes and shades. If you choose inexpensive stools at sales, you may encounter low-quality shaky construction and various defects.

To avoid unnecessary expenses, you should do make your own wooden stool. In this case, you get a structure of a certain size with an interesting and convenient design. Moreover, you will spend less money and can decorate the furniture to your liking. As a rule, the price of homemade wooden stools is lower than the market value. The disadvantages of creating a product with your own hands include the cost of materials. People who have little free time and virtually no construction skills may also encounter problems. However, if you wish, you can find the simplest drawings that even a schoolchild can handle.

In any case, when choosing a stool, you need pay attention to several factors:

- shape - any rectangular table will not fit well with round stools;

- type of upholstery - it is better to give preference to washable options, including leatherette or short-pile fabric upholstery;

- Dimensions – the seats must be of such dimensions that they fit under the table.

Requirements for a DIY stool

Essentially, a wooden stool is a versatile piece of furniture that can be pushed under a table or stored in a closet. Such an element can replace a stand, support or small table. To make a structure with your own hands, you can use waste from furniture production or leftover wood.

It is necessary to ensure that the finished wooden stool met a number of requirements.

- The furniture should be quite durable. This can be achieved by using high-quality glue and observing all technological standards. A durable stool will not fall apart, even if people wobble on it.

- An important requirement is functionality. So, the size and proportions of the stool must correspond to the height of all family members. For children, a stool with a crossbar to rest their feet would be ideal. The height of the seat must be correctly selected, otherwise the feet will not touch the floor.

- When choosing a seat, you need to pay attention to its comfort and compactness. If you make this element hard, it will not be usable for long. Soft stools are suitable for a conversation over a cup of tea. A respectable option is to use velor or leather as upholstery. Washable dermantine is suitable for families with small children or animals.

Preparing to create a stool with your own hands

It is always necessary to start with a drawing. To make a good stool, you need to approach the process responsibly. It is important to study the main options and choose the right one. Next, you should prepare a place to work and purchase everything you need.

Materials and tools that may be required:

How to make a stool with your own hands?

Classic wooden stool

To assemble such a structure you will need the following:

To assemble such a structure you will need the following:

- bars for legs or ready-made figured legs;

- kings;

- one-piece square seat;

- spacers

To prepare all these elements and assemble them correctly, you must strictly follow the drawing, which shows the dimensions. When the parts are ready, all that remains is to make the holes and do the dry assembly.

Simplified design

The easiest way is to make a stool, using blanks made in the workshop. A square made of laminate or parquet board is suitable as a seat. The drawers need to be glued to the finished base and additionally secured with screws. Then the holes for the legs are prepared here. A pair of legs are carefully inserted into the holes. Experts recommend fixing the finished structure using special glue.

Plywood stool

To make a stool that looks like a small bench, you can use pieces of plywood. It is necessary to prepare 2 pieces of thick plywood for the sides and one for the seat. In the upper part of the side elements there are holes for the drawers. Then you need to prepare places for fixing the spacers. All grooves are coated with wood glue. After this, you need to fix the drawers and work on the base of the stool. You need to prepare the holes here, insert plugs, apply glue and secure the top part. To make the structure really strong, you need to use 8 corners.

Make a stool out of wood or other material with your own hands is very simple. It is enough to prepare a drawing and the right tools. When the structure is ready, you need to start decorating it. Various materials can be used for these purposes. The main thing is that the stool fits into the interior.

Homemade stools

There are several options for making this piece of furniture, including wood.

There are several options for making this piece of furniture, including wood.

We will focus on the process of making a familiar wooden stool with our own hands. How to choose the right material, process it, correctly draw up a sample drawing - the article will offer detailed recommendations on all points.

All the stool drawings below are just examples. The process of their manufacture is not accompanied by precise calculations, as is required when designing load-bearing parts of any structure or those that are in one way or another subject to significant loads.

Therefore, below is only a recommended algorithm for making a stool yourself, that is, general instructions. Which model to make is up to you, dear reader, to decide. After all, it is clear that you can build anything with your own hands. The main thing is that the resulting sample fully corresponds to its purpose, which, again, is determined by the master.

Choosing a stool design

The given drawings and drawings clearly show which stool options are most often assembled for domestic use.

A more original option is a stool and a bedside table at the same time.

There is only one explanation - the more complex the configuration, the more time it will take to make the stool. But this is not the main thing. For various shaped elements, you will have to look for the appropriate tool, or even resort to the services of a person (or workshop) who has a machine, cutters, and the like for personal use.

A simple example: to make curly cuts, exactly along the radii, with just a hand jigsaw you can only make it out of plywood. And it is not a fact that the result will be satisfactory. If you plan to make the legs from a solid board, then if you have only the simplest household tools, it is better not to try - this requires many years of experience in processing wooden blanks.

Selection of materials

The fact that you will have to work with wood is understandable. But what kind of products can you use?

Solid wood in the form of boards and beams is suitable for the manufacture of any parts of the stool: seat (1), fastening bars (2), crossbars (3), legs, drawers and the legs themselves (4). A more simplified version is with a cover made of multilayer plywood. By the way, this solution has the advantage that it is easier to laminate the furniture panel (another name for this structural part) and, if necessary, replace it.

Type of plywood

It must be moisture-repellent. Water will definitely get on the stool during its operation. FBS products are the best in all respects, but their cost is such that not everyone will want to purchase such plywood. In everyday life, as a rule, products of the FSF and FK brands are used. To save money, you can buy cheaper sheets of these series, category Ш1.

This means that only one side of the sample was subjected to grinding. The condition of the second (wrong, back) stool seat does not matter. There is also a multilayer one with ready-made lamination on sale, but it will naturally cost more.

Wood species and material type

Let's start with plywood. If the stool will be located indoors, then the FC brand is better suited. It is less moisture resistant, but the glue used to hold the veneer together is not so toxic. But for this reason, FSF is recommended mainly for external use. In addition, its moisture resistance is higher. So if the stool will always be in the utility room, garden or somewhere else outside the building, this is the best option.

But you can write quite a lot about the choice of wood. Without going into the specifics of the different species, the author recommends using larch for the stool. Firstly, it is easy to process it with your own hands. Secondly, the cost of the material is quite reasonable. Thirdly, unlike many other species of coniferous trees in this price range, larch becomes even stronger when wet. Therefore, if you handle the stool carefully, it will last for decades. Fourthly, you will not need to constantly treat it with preparations against decay and biological pests. Other inexpensive options are acacia and ash.

Having chosen a specific type of wood, you should study all the features of working with it. But there are nuances, and it is this approach that guarantees that problems will not arise later. For example, does everyone know that acacia can be easily processed only after it is soaked? Dry wood from this wood is not much inferior to stone in hardness.

Wood moisture level

Basically, all wood must be properly dried. In construction it is prohibited to use these materials with an indicator of more than 20%. As for the stool, you don’t need to be an expert to understand that if you assemble it with your own hands from raw materials, after a while everything will have to be redone. The reason is trivial - the entire structure will “lead” after the wood shrinks.

Technology selection

There is often advice not to use tongue-and-groove joints. The main argument is complicated. But if you think about it, is this so?

In order to make grooves in the legs, the author used an electric drill with a small cutter. I first drilled holes along the marked lines, which I then combined, choosing “partitions” between them. No matter what anyone claims, this type of connection is the most reliable.

It is much easier to assemble all the elements with your own hands using self-tapping screws. The heads can be made secret and disguised. But such a design will soon begin to creak - it’s been checked. It turns out that the common element connecting the 2 workpieces is just a thin and short metal “pin” - the leg of the fastener.

Hardware can only be used as an additional (to glue-on) method of fixing parts. Elements such as corners, staples, and plates are also used for reinforcement. The master himself will understand what is more convenient for one or another version of the stool. And then, this is done mainly for bulky structures. If the product is small, then one glue is enough. Although the reader may have a different opinion, the author does not insist.

Manufacturing of components

The main parts of the stool are shown in the pictures (see above). If the drawing is ready, everything else is a matter of technique.

Assembly of the structure

This is, so to speak, a preliminary installation, a kind of “browsing” of the stool. At this stage, the accuracy of all dimensions, the correct fit of parts is checked, defects are identified (if any), and so on. Here you can still redo something, improve it without unnecessary costs and loss of time.

Processing of structural elements

After checking the readiness of the entire structure for assembly, the wood is “finished” - impregnated with special compounds, dried, and so on.

Assembling the stool

- It is advisable to start work from the seat. All crossbars, support bars and the like are attached to it - depending on the model.

- Installation of legs. They can be attached directly to the lid or assembled into a separate frame, with the installation of crossbars.

- Final assembly of the entire structure.

Grinding

After the stool is mounted, it needs to be given a “marketable” appearance. How and with what to treat the surfaces is determined by the master. This is done with your own hands mainly with sandpaper or using a special attachment that is inserted into the chuck of an electric drill.

Exterior design

Here the main advisor is your own imagination. Varnish, stain, paint – there are plenty of options.

The author deliberately did not indicate what specific cross-section and length the block would be needed, did not recommend a certain thickness of plywood sheets or boards, and so on, so as not to limit the reader in any way. If the meaning of the work - where to start and how to finish - is clear, everything else is unimportant. After all, when something is done with your own hands, it is a priori implied - AS I WANT, and not someone else.

Good luck with your home building!

A stool is one of the types of furniture and is intended mainly for use in the kitchen.

An ordinary, classic stool consists of:

- Cover - 1 pc.

- Legs - 4 pcs.

- Tsarga - 4 pcs.

- Legs - 4 pcs.

If someone wants to make a stool with their own hands, then no special difficulties are foreseen.

Of course, if you have never made wood, then on the first try you may not be able to make a high-quality and reliable stool. But this does not mean that you should not try your hand at carpentry.

Wood stool

If you decide to make a stool from wood, then for this purpose you will need:

- planed board, without knots, wormholes and splits, 25 mm thick.

- cranial block;

- electric saw or hacksaw with a small tooth stroke;

- countersunk screws 30 pieces per stool measuring 6x60 mm;

- screwdriver;

- metal square: it does not allow errors, unlike a wooden one;

- metal meter or tape measure;

- emery cloth;

- any small block, which we will wrap with sandpaper to sand the surfaces of the parts.

Preparing the lid

The lid must be square in shape and its dimensions can vary within:

- 32x32;

- 36x36;

- 40x40.

These are the most optimal sizes taken as the basis for the production of stools. However, since the stool is made independently, the body dimensions of family members can also be taken into account.

When buying lumber, keep in mind that it must be dry.

Dry lumber is planed without burrs, can be processed well with sandpaper, will not dry out in the future, screws will not fall out and the product will not turn into a wobbly stool.

Since this is our first time making a stool, we choose the size 40x40, this will make it easier to understand and learn how to work independently.

It is advisable to choose a board 20 centimeters wide, then there will be no need to plan off extra centimeters.

We saw off two pieces of 40 centimeters along the length of the board.

We take 40–60 K sandpaper, wrap it around a block and begin to clean the edges and ends of the workpieces. If there are clearly expressed irregularities on the plane, then we clean it with the same sandpaper.

At the second stage of cleaning, we use 80–120 K sandpaper. We also go over the plane, edges and ends.

At the final stage, we use 160–320 K grade paper.

It is possible that you may need another type of sandpaper: a lot depends on the type of wood and the sawing tool used.

Preparing the Tsargi

From a board 20 cm wide, cut off a piece 27-28 centimeters long.

We cut it on a circular saw into 4 parts of 5 centimeters each.

We take 40-60 K sandpaper and carefully clean the ends so that in the future there are no gaps between the drawer and the leg.

First, we clean the surfaces with sandpaper grade 80–120 K, then 160–320 K.

Preparing the leggings

We saw off a piece of the board the same length as the side. We cut 4 pieces of 3-4 centimeters each on a circular saw.

We take 40-60 K sandpaper and carefully clean the ends to avoid a gap between the rod and the leg. We clean the surfaces with sandpaper grade 80–120 K.

To completely complete the manufacture of the workpiece, we use 160–320 K sandpaper.

Cooking the legs

From a cranial block with a cross-section of 3x3 centimeters, we saw off 4 pieces 42 centimeters long.

Using sandpaper grade 40–60 K, we clean one end, which will be under the stool cover.

We sand the surfaces of the legs first with 80–120 K sandpaper, and then with 160–320 K sandpaper. The legs are ready.

Assembling the stool

We take two legs, lay them out on a workbench or table, with the cleaned end up. Between them on top, flush with the end of the leg, we lay a drawer. At the bottom of the legs, between them, at a distance of 10 centimeters from the bottom end, we lay a leg.

We fasten it with self-tapping screws on both sides, a drawer with legs and a leg with legs.

We do the same with the second pair of legs.

We fasten the remaining two drawers and legs with self-tapping screws, on both sides of the legs on one of the assembled structures, at the same level as the already installed elements.

We place the second assembled structure on top and secure it with self-tapping screws.

We place the assembled structure on its legs, distribute the blanks from the lid on top, and secure them with self-tapping screws.

The stool is ready.

Photo ideas on how to make a stool with your own hands

- Tool

- About the sizes of stools

- Three parts

- From 3 to 5

- Simple kitchen

- Spreader

- More connections

- Real kitchen

The world of stools is vast and varied; photo in fig. give only a general idea of its range. It is with a stool that many amateur carpenters begin their creative journey: you can make a simple, but practical and pleasant-looking stool with your own hands in half an evening, and in the future, stools of other types will allow you to master the essential subtleties of furniture craftsmanship, and not a single product will be superfluous in the house.

Other pieces of furniture do not have such amazing properties; This is explained, on the one hand, by the fact that the stool is essentially extremely simple, purely practical and comes from ancient times: the wooden logs on which cavemen sat around the fire are already stools. For the same reason, a stool must endure everything, be strong, reliable, and durable.

On the other hand, the simplicity of the form and design allows the stool to fit into any interior and generally be at home in any environment. Over the centuries and millennia, this certainly had to be appreciated, and was appreciated, as a suitable basis for the embodiment of certain aesthetic concepts in the material. Such an exquisite piece of furniture as a banquette is also nothing more than a stool. Ornate design and decor require the use of complex technological techniques, so to make a luxurious stool, you will need a fair amount of skill and experience. It is much easier to purchase both when working with a familiar base, and here the stool provides a full range of products from the completely primitive to the most technologically sophisticated.

Stools are made from a variety of materials, from rope to stone. Plastic stools have long been commonplace, and forged or welded metal ones are also not unique, but in this publication we will figure out how to make a stool from wood. The reason, in addition to the “originality” of the material, is that it is a wooden stool can be extremely simple, durable, reliable, and at the same time have high aesthetic merits. How so? Well, let's go!

Tool

Making a stool begins with preparing the tool and workplace. Don't worry, we won't immediately advise spending a decent salary on a wood milling machine, drilling machine, planer saw and lathe. Let's try to do without even a carpentry workbench. Maybe it will come to all this when a taste for work appears and income from it appears. For now, we will limit ourselves to the minimum that will allow us to work from a table on the balcony or in the garage, laying a film on the floor so as not to spread sawdust. And this minimum of tools should be useful on the farm in general, in case (everyone has their own inclinations) the first stool turns out to be the last.

So, to begin with, in addition to an electric drill, you will need a pair of C-shaped carpentry clamps for 180-220 mm (top left in the figure), one (preferably 2) F-shaped for 400-500 mm, at the top in the center, and, preferably, clothespin clamp, top right. They are inexpensive, and their range of applications besides carpentry is very wide.

Buying a jigsaw, of course, would be a good idea; it is not that expensive and is suitable for a wide variety of jobs. But at first, you can use it instead... a frame hacksaw for metal; These are also sold as mini hacksaws. Just don’t take entirely plastic ones (bottom left in the figure, pos. a). This is a tool for rare occasional use. Such a miracle can be found on the Internet for as much as 18 rubles, but the plastic sponges are quickly eaten up by the steel of the blade, and an “ultra-cheap” hacksaw is not enough for a good stool. You need to take a mini hacksaw with a steel frame, pos. b. It will cost about 50 rubles, but you can work with it for a long time and regularly.

To work on wood, the blade is inserted into the frame hacksaw “incorrectly”, with the cutting edges of the teeth towards you (upper insert in pos. b). Then, using a section of the canvas in the frame, you can saw across the grain, along and obliquely. In any case, the cut comes out even and smooth, literally mirror-like; When sawing layer by layer, only under-dried or newly damp coniferous wood becomes a little shaggy. In this way, for example, the tenons for the groove are filed, see below. Again, the “wrong” way to cut wood with a frame saw is to start from the corner, because wood is softer than any structural metal.

Using a protruding section (cantilever) of the blade to make a curved cut is slower than with a jigsaw, but, with some attention and accuracy, just as accurate. When working at home, it is advisable to thread the blade, as it should be in a mechanic's fashion, with the ridges of the teeth away from you, so that the sawdust falls down, clogging the markings. In this case, you also need to saw like a metalworker: hold the tool level, without tilting it along the cut, do not lean too hard, and allow a swing (working stroke) of no more than 1.5-2 widths of the blade. Also, with the “wing” of the blade, the protruding ends of dowels and through tenons are sawed off no worse than with a special flexible saw, which is several times more expensive.

Next, wood files - rasps. You will need 2 of them: straight semicircular 200x20 mm, pos. in, etc. cabinet, also semicircular (250-300)x30 mm, pos. d. A cabinet rasp differs from a straight rasp not only in its narrowed end, but also in the method of notching. Both of them have a notch, of course, that is not at all the same as that of metal files; those on the tree instantly become clogged with sawdust. Depending on the properties of the wood and the area being processed (end, edge, face), it may be more convenient to work with one or another rasp.

Then, chisels. We will need simple straight wood chisels with a width of 6-8 and 20 mm. It would also be a good idea to purchase a set of 6-40 mm chisels, consisting of 3-5 samples. Often a set of chisels comes with a wooden mallet, which otherwise needs to be purchased separately. However, you can make a mallet, like a clothespin clamp, with your own hands from hard, fine-grained wood.

About the sizes of stools

The dimensions of the stool seat, as a rule, are taken in the range from 300x300 to 450x450 mm or, if the stool is round, of the same diameter. Minimum – 250x250 mm; sitting on a 200 mm board is already uncomfortable; after 5-15 minutes, the edges of even a soft, but too narrow seat crash into the vast elastic “fifth point”.

The total height of the stool is taken, according to height, in the range of 420-480 mm. The height of a children's or utility stool can be reduced to 260-280 mm; in this case, the seat is made approximately 260x260 mm or with a diameter of 270-280 mm.

Note: When designing a stool yourself, you should remember that the contour of its supporting surface must be no less than 280x280 mm or a diameter of 320 mm for a stool of normal height and no less than 250x250 mm or a diameter of 290 mm for a stool of reduced height, otherwise both will turn out to be unstable. For decorative and folding stools, these values can be reduced by 1.25 times.

Three parts

Yes, a good stool, incl. decorative for the living room, can be assembled from just 3 parts. Drawings of a product of this kind (stools-cabinets) are given on the left in Fig. The version of 4 parts is unsightly, but very durable, therefore it is more suitable as a working stool: you can attach a removable vice on it, drill, saw, chop, etc. In this case, it is better to take the overall dimensions of the 4-piece stool to be minimal, see above.

The sample on the left in Fig. – one of the very few types of stools that can be made entirely from chipboard with a thickness of 20 mm or more; The width of the connecting grooves in the parts corresponds to the thickness of the material. The base is assembled with glue (carpentry glue, nitro glue for wood, PVA or polymer for tiles like bustylate). Seat fastening – wood self-tapping screws or confirmatory screws (60-90) x 6 mm. Screw connections are also glued.

The fact is that chipboard really “does not like” loads on the layer and fastening at the end. In this design, the loads concentrated at the attachment points spread well and, if assembled correctly, delamination of the material is unlikely. But it is still highly advisable to glue pads made of hard, dense wood (oak, beech, hornbeam) with a thickness of 10 mm or more onto the heels of the legs. No need for rubber, it will stain and ruin the floor.

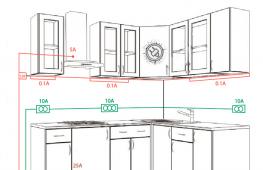

From 3 to 5

The version of the supporting structure of the stool, shown on the right in the figure, allows, on the one hand, to get rid of the rather labor-intensive and responsible cutting of long, even grooves, which is especially important when working with a hand saw. On the other hand, it allows you to get legs of a rather bizarre shape without a significant increase in material waste, because workpieces are marked with minimal technological gaps on a board 200-250 mm wide.

The “highlight” here is that 2 of the 3 parts of the previous design (namely, the legs) “halve” lengthwise. The base is assembled in a cross (diagram at the top right) similar to the previous one. option, i.e. with gluing all connections:

- Drill holes for self-tapping screws; You don't have to select holes for the fastener heads.

- Dry assembly is carried out and, if necessary, parts are adjusted.

- Inject 3-4 drops of glue into the holes under the fasteners and spread it inside with a thin splinter.

- Apply glue to the mating surfaces.

- Maintain parts until the glue sticks to visible surfaces.

- The entire assembly is assembled quickly and tightly using hardware.

Pay also attention to the side surface, marked with the letter A. Before installing the seat, you can put on a round shell, rolled from thin fiberboard. The shell is installed using glue and small hardware (screws, nails). After assembling and finishing the entire product, the shell can be decorated, incl. very impressive stucco molding from polymer clay and get a truly luxurious stool.

4 parts

Stools-benches of a box-shaped design made of 4 boards (a seat, 2 side panels-legs and a vertical longitudinal insert-support beam, on the left in the figure) are widely known and have been described many times. However, such a stool is simple and cheap only in appearance: for proper strength and reliability, its parts need to be cut from a block of durable wood or chipboard with a thickness of 40 mm and a width of 250 mm. Both materials are not cheap; scraps suitable for a stool most often do not go to waste, and it is not easy to find them for sale or in your own pantry.

Meanwhile, a utility and work stool-bench can be made literally from scrap materials, scraps of timber from 30x30 and plywood from 2.5 mm as follows, on the right in the figure:

- Sections of timber are welded into panels (leg blanks) end-to-end with glue, as described below;

- One side of each panel is covered with plywood under pressure (compression with clamps);

- Cut out corner grooves in the leg blanks for the same beam and use a chisel to select holes for the screed from the same beam;

- Cover the front sides of the legs with plywood in the same way as in step 2;

- Assemble the supporting box of the stool using glue and self-tapping screws;

- The seat is attached, which in this case can be made of plywood from 6 mm or boards from 12 mm. You can simply install the seat on the glue; all operating loads are already taken care of by the box.

Simple kitchen

A simple full-size utility stool can also be made from scraps of timber, plywood or chipboard, see fig. It is more suitable for a seasonal garden. When used in the kitchen of a residential building, the design turns out to be rather weak, where this stool lasts for 3-5 years. The second option for using the same design is a smaller children's stool, see above; the dimensions of the parts are then proportionally reduced, except for the width of the connecting grooves.

Spreader

A step stool with 2 pairs of X-shaped legs is also quite popular due to its low material consumption and good decorative qualities. However, in reality it turns out to be not so simple.

Take a look at the subassembly marked in red in the fragment at the top left of the figure. Performing a strong and reliable insertion of 3 beams in 2 mutually perpendicular planes is not an easy task even for an experienced carpenter; putting a dowel there will be unreliable, and the self-tapping screw in this case is outright hackwork: the double crosshair is heavily loaded and the steel hardware will tear the wood.

These problems can be circumvented by combining the beam and box-type load-bearing circuits of the supporting structure. We will leave the openwork of the beam frame in the most noticeable place - at the bottom - and we will achieve overall strength with an “oak” box-shaped top. Technically, this is achieved by reducing the angle between the legs to 60 degrees. Then, in order to maintain the overall height of the stool and the width of the contour of the supporting surface within acceptable limits, the crosshairs of the legs move upward. The V-shaped part of the now asymmetrical X is high and wide enough that a strong box can be made from 20 mm or thicker pine boards, chipboard or plywood, see left in figure.

Note: the missing overall dimensions can be taken from the figure; it is drawn to scale.

The longitudinal walls of the box do not have to be inclined; This is done to reduce the visibility of the box while maintaining maximum volume. If the longitudinal walls of the box are straight, it can be made narrower, as long as the V-shaped part of the legs fits inside. It also doesn’t hurt to deepen the box by moving its bottom down; the whole stool will only be stronger. In this case, 1-2 attachment points are added to the ?-shaped parts of the legs, similar to the V-shaped part, marked in green in Fig. The box is assembled on dowels (see below) and glue or on steel corners applied from the inside. In this case, the box is first glued, and after 1/4-1/3 of the time the glue has completely hardened, it is finally fastened with steel.

First, when choosing excess from the groove (pos. 1d), there is no need to bring it to complete rectangularity. It is better to leave the edges (short sides) of the groove rounded, and round the edges of the tenon accordingly, so the entire connection will be stronger.

Secondly, the tenon does not have to be made on a router; it will not take much longer to cut it out by hand with the same frame hacksaw. First, at the level of the base of the tenon, the workpiece is sawed across the contour 0.5-1 mm less than the required depth, retreating from the markings to the end of the workpiece by 0.5-1 mm. Drilling down to the full depth is also not a big sin, but then a shallow narrow groove will remain along the contour of the base of the tenon. If you don’t finish sawing a little, then the base of the tenon, due to the elasticity of the tree, will be slightly wider, and the whole connection will again be stronger.

The tenon is finally cut out from the end along the fibers, retreating 0.5-1 mm outward from the markings. Here, for the same reason, the cut is also not completed by 1-1.5 mm, and the excess is simply broken off. If the wood is straight-grained coniferous, the excess will at some point crack on its own and hang on the fibers or fall off. Adjust the tenon to size and round its edges with a rasp.

Note: When developing wooden structures yourself, do not forget - all tenons should be directed only and only along the layer! The thickness of the tenon for ordinary industrial wood, unless otherwise indicated on the drawings, is taken by default at 1/3 of the thickness of the thinnest of the mating parts.

As for dowels (round connecting bosses), it is better to buy ready-made wooden ones. The cost of ready-made dowels is cheap; they are already chamfered and grooved, which makes the glued connection stronger. Plastic dowels do not dry out along with the wood and therefore the connection weakens over time.

The main rule when choosing dowels is that their wood should dry out a little slower than structural wood or at the same speed; this condition is almost always met if the wood of the dowel is harder. Drying out the dowel is difficult because its contact with air is limited. As the part dries out, it will compress the dowel; The lignin between it and the dowel is gradually “soldered together” and the connection becomes stronger over time.

The diameter of the dowels is taken to be 2.5-3 times less than the thickness of the narrowest part to be connected; its length is 1.75 times the thickness of the thinnest part. The last dowel (if it is not through) should fit 2/3-3/4 of its thickness, and the rest of it should sit in the thicker part.

Note: holes for blind dowels in thin boards are selected so-called. with a Forstner drill, see below, leaving behind an almost flat bottom.

Also a useful stool

Well, are you going to make a tenon and groove with your hands? Then it’s time to start making a simple folding wooden stool, see picture, for a summer house, garden, picnic. 2-3 of these stools will not take up much space in the closet and will fit in the trunk of a car. Material: board or plywood. It is highly advisable to impregnate all parts from the latter with a water-polymer emulsion before assembling the product; it will not only protect against moisture and rot, but also strengthen the structure.

How to make a grab

Taking a folding stool with a round seat simply by the seat is not entirely convenient, so the hand grip on the sample above is not a whim. In a solid board, the grip is cut out as usual: using a feather or core drill, holes are drilled along its edges (diameter - 24-36 mm; distance between centers 95-115 mm, depending on the hand), and the excess between them is sawed out. In this case, it is also convenient to use a frame saw.

It’s another matter if the grip is at the junction of the boards; This most often happens in classic kitchen stools, see below. Here the beak of the feather or the pioneer drill/guide pin of the crown when working with a hand drill will definitely go along the groove and the drill will lead to the right. A jig made of thick plywood or cutting a board does not help, the thin side of the feather or the teeth of the crown tear it, and they themselves catch on the steel jig.

It is for such cases, as well as for drilling holes with a flat bottom, that the Forstner drill is intended, see Fig., its side surface is smooth. When making a hand grip in the seat of a stool, first drill holes in the jig according to the dimensions indicated above; there is a surplus left! The jig is then placed in place, securely secured with a pair of C-clamps, and the edge holes are drilled. The excess in the part is chosen as always; the gap between the boards is not a hindrance for this.

Real kitchen

Now we have classic stools for the kitchen. During use, they suffer more than others, so their design is carried out according to all the rules of strength: a rigid beam frame, capable of withstanding all operating loads, and a seat that must be held firmly in place, but in such a way that, if necessary, it can be easily repaired or replace. Therefore, the seat of a kitchen stool is made of panel boards from cohesive planks (see below) and attached to biscuit stands or directly to the frame on dowels.

The option with breadcrumbs is shown in rice; pos. A – its general diagram and names of its components. The advantage of this design is the low requirements for the quality of the seat shield. By installing a pair of crackers on each drawer (this will not reduce the overall strength of the product), you can make the seat out of separate boards, and on the original 4 crackers - with plywood or chipboard.

Pay attention to the drawers, these are not just boards, they are all over the furniture, and not only in furniture. In general, a drawer is a part that properly distributes loads in an assembly unit and is itself capable of bearing the load. Drawers can be found in the still, pipelines, etc., which have nothing to do with furniture.

Also pay attention to pos. E, it shows a way to check the evenness of pairs of legs using diagonals; it is basically the same as checking the squareness of the foundation. When assembling a classic stool, the evenness of the pairs is checked three times, see fig. right: in pairs assembled separately (left pose and red lines), between pairs (orange lines on the central pose) and the overall rectangularity of the frame (brown lines in the center). The seat is installed only after complete check of levelness; filing the legs of a finished stool is complete unprofessionalism.

Below in Fig. – drawings of a stool for the kitchen with a seat mounted on dowels. This design is less labor-intensive and material-intensive, because operations for the manufacture and installation of crackers are eliminated, but the seat panel must be firmly solidified, see below. If the frames are installed on the legs, they should not reach the floor by 20-40 mm, so as not to scratch it.

Note: The cuts of the tenons at 45 degrees in both cases are made with the same frame hacksaw. A fixed miter box (device for sawing at an angle) at fixed angles of 90, 45 and 60 degrees costs no more than 50 rubles.

How to join boards into a shield

The boards that will now be the plots of the set (package) are usually joined into boards with glue using special clips - weims, top left in Fig. In weims, small additionally secured shields, like for the seat of a stool, can be simply joined together end-to-end. Large panels, say, for a table top or the side of a cabinet, are joined together (middle row from left to right) with a tongue and groove, in a rebate, on dowels, dowels (lamellas) and other methods.

In handicraft work, clamps are sometimes replaced with various homemade devices on the same principle (compressing the set with pairs of wedges), at the top right, and now more and more often with large F-shaped clamps. In this case, a rather labor-intensive preparation of the plots is necessary for consolidation using methods a, c or d. However, there is still no guarantee that the set, when compressed, if it does not rear up all like an accordion, will go in a wave, because It is impossible to achieve absolutely precise mating of wooden parts under load due to the low local strength of the wood.

However, there is a way to attach the shield to the seat of a stool end-to-end, completely even and without complex devices, this is the so-called. twisted rim with cheek liners; its diagram is given below in Fig. Step-by-step bonding of the shield in a twisted wire is carried out as follows:

- The lower (according to the diagram) plywood cheek is placed on the table;

- The table with the cheek is covered with plastic film;

- Glue is applied to the edges of the plots and kept until tack-free or according to the glue instructions;

- The plots are placed on the lower cheek on top of the film and, if possible, squeezed tightly with your hands;

- Wrap the set in film;

- Apply the upper cheek;

- The entire package is carefully, without lifting or turning over, moved to the edge of the table so that some part of the set hangs above the floor;

- Begin winding the cord, applying the turns as tightly as possible, but not too tightly;

- When the bag is wrapped about 1/3 or more, it can be removed from the table and wound by weight;

- The ends of the cord are tied;

- Insert wedges under the winding, tapping with a mallet. You need 4 wedges, they are inserted evenly from 4 sides (2 from above and 2 from below), tapping alternately;

- When the wedges pull all the turns of the winding tightly evenly, the bag is left until the glue dries completely;

- After the glue has dried, the winding, cheeks and film are removed, and the set is cut to size.

The cross section of the wedges does not have to be rectangular; it is possible to use round sticks cut obliquely; There is only one condition - the wedges need to be smooth. It is advisable to use a slippery propylene cord; packaging twine will do. The thickness of the wedges is determined based on existing experience. If there is none, then the package is first assembled dry, without glue, and the thickness of the wedges is selected so that they fit completely under the winding, pulling its turns tightly.

How about softer? DIY stool covers

Sitting on a hard one for a long time is understandably unpleasant. A comfortable stool on a classic kitchen frame can be made with a wicker seat, without bothering with breadcrumbs, dowels and a shield, see fig. The seat material is colored propylene twine and smooth linen cord.

It is highly desirable for decorative stools in the living room to be beautifully soft, and it wouldn’t hurt to give a kitchen stool some shine. But there is not and cannot be a stool on which no one would ever stand. Or, at least, he did not feel a strong desire to do this for completely objective reasons caused by the prevailing circumstances. Hence the conclusion: the stool needs a soft, elegant pad on the seat - a seat - which, if necessary, could be removed without fiddling for a long time, and just as quickly put back.

The first thing that comes to mind in this case is a decorative pillow, see for example. video below. But the pillow can be accidentally dumped on the floor, and it itself will slowly slide down there. Another option is a case with a soft liner. A cover for a chair or armchair is a rather complex sewing product, but with a stool the situation is simpler.

Video: decorative pillow on a stool/chair

Covers for stools are made mainly of the following types, see fig. Pos. 1 – cape with ties. This is the easiest thing to sew, but the ties stick out in plain sight, and there is a lot of fiddling around with them, especially if the stool is for children and the baby has figured out something of his own with the knots.

The next option is a cape with an elastic band. She can look great, pos. 2, and you can remove it by simply pulling it off. The structure of a stool cover is generally the same as permanent soft upholstery: from bottom to top, foam rubber, synthetic padding and upholstery fabric, but there are a couple of tricks here.

Firstly, it is better to take foam rubber from PVC, yellowish soft, pos. 3. It is not suitable for permanent upholstery of furniture, because... relatively short-lived. But in the case of a stool, another feature comes to the fore: it adheres well to wood, incl. varnished, so that the cape will not slide to the side and under the angry rider.

Secondly, it is better to cut the cover for a square stool diagonally, i.e. The warp and weft of the fabric should go from corner to corner. In this case, there is no need for cutting as such: the cut is thrown onto the seat (the folds create beautiful and smoothly fitting corners), where to cut is marked, cut and sewn.

Note: the cover for the round stool needs to be cut; an example of its manufacture - see the video below:

Video: simple do-it-yourself cover for a round stool

An option that is also quite soft, original, beautiful and grippy to wood is a rug for a stool using the patchwork technique, i.e. patchwork, pos. 4; see e.g. plot:

Video: seat-mat on a stool using patchwork technique

Finally, a knitted cape, pos. 5. This option is labor-intensive and almost exclusively decorative. It allows you to achieve a magnificent visual effect, but, alas, a knitted cape will retain its appearance for a long time only on a stool that is not sat on.

In conclusion: immediate aerobatics

Stools with diverging legs are very elegant. It is generally accepted that they are not for everyone. The reason is drilling holes at a precisely specified angle; see fig. for example. drawings of details of a stool with turned legs. Here, firstly, you cannot do without a drilling machine. A relatively inexpensive benchtop stand for a drill does not help: the shaft cage in it is too short, which is why, in combination with the plastic body, the drill moves by half a degree, or even more. Such an error is enough to make the stool crooked and shaky.

Secondly, adjusting the parts of a stool of this design during the assembly process is excluded; everything must be done immediately exactly to size from solid, high-quality wood. See the steel plate at the bottom right in the picture? This is a gauge for checking the diameter of studs. In this case, regardless of the design and overall design, they must be round, i.e. You also need a wood lathe.

Now let’s go back to the “3 to 5” stool. Let's reduce the size g to 100 mm, this is acceptable. Is it now possible to make this stool with spreading legs? Quite. They will, of course, not be chiseled and not quite round, but the grace and lightness of the stool will be preserved. This is what the aesthetic potential of a stool means in practice.