Industrial premises lighting project. Designing lighting for a production facility Designing electrical lighting for a production facility

For proper safety and comfort in workplaces in the workshop, first of all, high-quality lighting must be provided. In this case, “quality” means the following characteristics:

- Efficiency – the ability to quickly reach operating mode without high starting loads on the network, as well as rationally distribute the light flux;

- Safety – both for the main workshop workers and for those whose responsibilities include servicing lighting systems.

- Cost-effectiveness – the ability to provide the luminous flux of the required power at the lowest possible financial cost.

- Meets industry standards for lighting requirements.

Light Smart company equips lighting for industrial buildings, including workshops and workplaces, administrative buildings, adjacent areas, as well as temporary structures and construction sites. In our work, we rely on truly high quality of light and energy efficiency of the system within the functioning of the enterprise, therefore we choose LED lighting systems.

A range of services from Light Smart

The range of services for arranging lighting for an industrial building includes:

- calculation of artificial lighting of industrial premises;

- design of artificial lighting of premises;

- selection of lighting fixtures;

- installation of fastening systems (consoles, suspensions, brackets for placement on the wall);

- installation of lighting fixtures;

Stages of drafting projects

01 Examination of lighting installations

Verification or measurement of room dimensions and equipment layouts. Collection and analysis of information on the current state of the facility and the equipment used

02 Lighting concept development

Determining the required level of illumination, carrying out lighting calculations, recommendations for choosing specific models and the number of lamps, developing a layout of lighting devices, calculating the required electrical power to implement a lighting solution

03 Preparation of project documentation

Lighting design of stage P and P lighting; electrical design of stage P and P lighting; drawing up estimates and preparing a feasibility study for the implementation of the selected lighting solution

04 Additional materials

Feasibility study for the implementation or replacement of current equipment with LED

By ordering the modernization of lighting in any workshop from us, you will quickly receive an energy-efficient system that turns on instantly, does not have a stroboscopic effect, and is shock-, dust- and moisture-proof. We strictly comply with industry lighting conditions for industrial premises, while at the same time minimizing electricity costs and freeing up additional energy capacity. Find out more from our specialists:

- Come to the company office - Moscow, st. Shabolovka 34, building 3;

- Call us +7 495 236 70 63;

- Write to e-mail info@site.

A project is an image of a future device or structure (system), presented in drawings, diagrams, tables, descriptions created on the basis of calculations and comparison of options.

For large and complex industrial complexes, buildings and structures, the lighting installation project is developed in two stages: technical design and working drawings.

Technical design of electric lighting for industrial premises

In the technical project, issues of the lighting and electrical parts of the lighting installation are resolved, assignments are issued for the design of power supply and basic construction solutions.

Working drawings of electric lighting of industrial premises

Working drawings are developed on the basis of the approved technical design.

The development of a technical working draft or working drawings should be carried out in accordance with the environmental conditions in the premises, in full compliance with the groups and categories of the environment, data on the power sources of the lighting installation must be established. When designing, it is recommended to study in detail the technological process of the illuminated enterprise and know the nature of the visual work performed in the premises.

The plans of the power supply network show the construction part of buildings in a simplified manner, display panels that indicate the number and installed power, and draw network lines indicating the brands and cross-sections of cables and wires. On the plans of the main premises, the installation locations of lamps and panels are fragmentarily outlined. Lamps, panels and various equipment are calculated according to plans and a table of indicators.

Drawings of plans and sections contain basic information about lighting solutions and the electrical part of lighting installations.

Drawings of plans and sections contain basic information about lighting solutions and the electrical part of lighting installations.

When developing plans, it is necessary to use a set of symbols and requirements for the implementation of inscriptions and numbers specified in GOST 21-614-88.

The plans include lamps, main points, group panels, step-down transformers, supply and group networks, switches, plug sockets; the names of the premises, the standardized illumination from general lighting, the class of fire and explosion hazardous premises, types, installation height of lamps and lamp power are indicated. , methods of wiring and cross-section of wires and cables of lighting networks. The reference dimensions of installation locations for lamps, panels, and marks for laying lighting networks are indicated in cases where precise fixation of these locations is necessary.

When designing buildings, a number of rooms of which have the same lighting solutions: lamps, lighting network and other identical elements, it is recommended that all solutions be applied only for one room; for others, an appropriate reference is made to it. The general floor plan shows only the entrances to such premises. Drawings of floor plans of all premises are made on a scale of 1: 100 or 1: 200.

When designing buildings, a number of rooms of which have the same lighting solutions: lamps, lighting network and other identical elements, it is recommended that all solutions be applied only for one room; for others, an appropriate reference is made to it. The general floor plan shows only the entrances to such premises. Drawings of floor plans of all premises are made on a scale of 1: 100 or 1: 200.

In addition to drawings of plans and sections of illuminated premises with lighting diagrams printed on them, the design documentation includes: custom specifications for electrical equipment and materials; construction buildings; remote control diagrams or other circuit diagrams, non-standard installation drawings.

Supply and group networks on floor plans are drawn with thicker lines than the building elements of the building and equipment; the number of wires in group lines is indicated by the number of notches drawn at an angle of 45° to the network line.

Indication of groups throughout is necessary to ensure uniform phase loading. On panels without factory numbering of groups, connection phases are indicated. The plans include summary data, network voltages, links to symbols, and grounding information.

Electric lighting is divided into working, emergency, evacuation (), and security. If necessary, some of the luminaires of one or another type of lighting can be used for emergency lighting (lighting during non-working hours). Artificial lighting is designed in two systems: general and combined, when local lighting (workplace lighting) is added to general lighting.

Working lighting should be installed in all areas of buildings, as well as in areas where work is being carried out and vehicles are moving.

The calculation of a lighting installation consists of two parts: lighting and electrical.

The lighting part contains: selection of light sources, standardized illumination, type and lighting system, type of lamps, safety factors and additional illumination; calculation of the placement of lamps (determining the height of the suspension, the distance from the walls and between lamps, the number of lamps), luminous flux and lamp power.

Purpose of lighting calculations

Lighting calculations allow you to do the following:

a) determine the number and unit power of light sources of the lighting installation that provides the required illumination in the room (on the working surface);

b) for an existing (designed) lighting installation, calculate the illumination at any point on the surface of the illuminated room;

c) determine the quality indicators of the lighting installation (pulsation coefficient, cylindrical illumination, glare and discomfort indicators).

The main lighting engineering calculation of lighting is to solve problems according to the above points a) and b). For this purpose, the following methods are used: the luminous flux utilization coefficient method and .

Classification of lighting engineering methods for calculating lighting

Luminous flux utilization factor method used to calculate the overall uniform illumination of horizontal surfaces, mainly to calculate the luminous flux of the light source(s). This method also allows you to calculate the average illumination of a horizontal surface, taking into account all the fluxes incident on it, both direct and reflected. It is not applicable for uneven placement of lamps or calculation of illumination at characteristic points of both non-horizontal and horizontal surfaces.

A simplified form of the luminous flux utilization factor method is power density method per unit of illuminated area. This method is used for approximate calculations of overall uniform illumination. The maximum calculation error using the power density method is ±20%.

The point method for calculating lighting allows you to determine the illumination at any point on the surface of the illuminated room for any uniform or uneven placement of lamps. It is often used as a verification method for calculating illumination at characteristic points of a surface. Using the point method, you can analyze the distribution of illumination throughout the entire room, determine the minimum illumination not only on a horizontal, but also an inclined surface, and calculate emergency and local lighting.

The point method for calculating lighting allows you to determine the illumination at any point on the surface of the illuminated room for any uniform or uneven placement of lamps. It is often used as a verification method for calculating illumination at characteristic points of a surface. Using the point method, you can analyze the distribution of illumination throughout the entire room, determine the minimum illumination not only on a horizontal, but also an inclined surface, and calculate emergency and local lighting.

The main disadvantage of the point calculation method is that it does not take into account the reflected light flux from the walls, ceiling and working surface of the room.

In cases where none of the above methods can be applied, for example, when calculating uneven lighting of a room with significant reflective properties of walls, ceilings and working surfaces, then both methods are used, acting in a combined manner.

The electrical part of the project contains: selection of locations for main and group panels, network route and layout, type of wiring and method of laying it; calculation of the lighting network based on permissible voltage loss, followed by checking the cross-section for continuous current and mechanical strength, protection of the lighting network; recommendations for installing a lighting installation; measures to protect against electric shock.

Designing lighting for industrial premises is a labor-intensive and costly technical task. Its implementation presupposes strict adherence to established standards and requirements of current legislation.

The organization of supply and distribution of light covers workshops, administrative areas, warehouses, and areas on the territory of the enterprise. Its competent implementation helps the successful functioning of the company, especially in a continuous cycle that involves shift work of employees.

Proper planning of electrical networks and equipment ensures:

- safety;

- compliance with hygiene and sanitary standards;

- convenience of personnel, taking into account production specifics;

- improvement of the security system.

If the first three points comply with the SNiP acts, the management will not have any further claims from the energy supervision service.

Norms and requirements

The complex of calculations, which is directly related to the choice of quantity, modification and location of lamps, is carried out only by specialists from the contracting organization who have special permission and appropriate certification. When creating lighting projects for industrial enterprises, electricians perform a task that includes the main criteria:

- Ensure the quality of artificial light.

- Achieve a reduction in energy losses.

Based on the relevant experience of industrial organizations, the state has created uniform standards for the development of plans for operating facilities and those under construction:

- administrative buildings;

- domestic buildings;

- workshops

Underground, construction and transport sites are not included in this category, since the principle of lighting is determined by other acts.

To design interior lighting, they rely on several SNiPs, instructions and GOSTs for the preparation of documentation and technical specifications.

Quality indicators and standards

The wide range of lighting products on the market includes:

- diodes;

- lamps;

- installations for industrial use.

Based on the requirements of the design documentation, all equipment elements are selected so that they have:

- resistance to mechanical damage;

- strength;

- economical consumption of electricity;

- long service life.

Please pay attention to:

- room area;

- the presence of vibrations emanating from the production process;

- air pollution (with a large percentage of this indicator, the lamps will often become clogged, you will need to allocate time and money to clean them);

- taking into account the features of natural lighting.

Such lamps are economical and pay for themselves in a short time. Sufficient illumination of workplaces presupposes:

- Increased output.

- Reducing worker injuries.

- Comfort of staff activities.

According to SNiP 23-05-95, electrification quality standards must meet the following requirements:

- uniform light flux;

- absence of areas of possible blinding;

- eliminating blinking, which is harmful to the health of employees.

Types of lighting in enterprises

Each organization is equipped with several lighting systems that differ in purpose and technical features.

Mandatory electrical installations are divided into 2 types:

- Basic. Used for arranging workplaces and setting up a continuous technical process.

- Emergency. Serve to ensure the same goals in the event of a power outage due to an emergency situation - fire, explosion and other emergencies with possible harm to health and threat to human life. They are supplemented by other electrical networks and devices that are activated during evacuation.

Light sources used under extraordinary circumstances are installed in premises that ensure the normal functioning of enterprises and in places for quick opportunity to leave the building:

- in communication centers;

- ventilation hatches;

- on stairs;

- in control centers;

- cramped corridors;

- where there is no natural light.

For these types of electrical systems, regulations allow for uneven distribution of luminaires.

There is also a duty switching on of light sources - it is used during non-working and dark times of the day. In this case, the standards are not spelled out, which allows the directorate to independently establish its quality indicators. In order to save money, many use evacuation electrical equipment for this.

Lighting part of the project

In addition to dividing by main types, lighting of industrial buildings and premises is classified according to systems that are strictly regulated by technical documentation. According to this, the types are distinguished:

- General artificial. Assumes an even distribution of ceiling lamps in a checkerboard or rectangular pattern.

- Localized. This is a directed flow onto a separate work surface. Lamps can be stationary or portable.

- Natural. It does not provide the required degree of illumination, but its use is encouraged. Even large windows will not be able to provide full quality light to remote areas.

When developing a project, it is considered the optimal solution to correctly combine the natural flow of rays and electricity, creating a combined type.

The intensity of illumination of working surfaces depends on the specifics of visual work. Based on the size of the object being produced, actions are divided into 8 categories:

- 1st - with the highest lighting needs, these are objects not exceeding 0.15 mm.

- From 1st to 5th, the use of general lighting is prohibited; these include products 0.15-5 mm.

- From 5th to 7th - larger parts.

- 8th - only observations of the person responsible for the process are included in this category, so the source is selected according to the level of complexity of visual work.

The quality of task performance depends on the degree of comfort of employees, therefore the management of any enterprise is obliged to comply with the established standards prescribed in the lighting part of the project.

Technical component of design

Industrial lighting projects include an electrical part. Its development uses information about the operating conditions of the equipment. For this purpose, data is collected:

- on the presence of explosive and fire hazardous areas indicating the class;

- about the possibility of formation of explosive mixtures, gases, vapors with air, hazard category.

Depending on this, the appropriate electrical equipment is selected. One of the most difficult calculations is the calculation of voltage loss in networks, because the load is distributed along the entire length of the group.

Selecting light sources

To correctly select power plants, enterprises rely on the basic technical requirements of regulatory documents - instructions, SNiP, GOST. They come down to points that provide:

- employee safety;

- access of the repair team to the equipment;

- normalized lighting level;

- compliance of electrical equipment with the principles of efficiency;

- quality of light, including uniformity of distribution, absence of glare, dark areas, pulsation;

- ease of installation of networks, their short length;

- special reliable fastening that prevents accidental falling of the lamps.

Compliance with the purpose of the energy system at the enterprise is possible only taking into account the production specifications. These include:

- Working conditions in the workshop - dust, chemicals, humidity.

- Architectural features of the premises - height, area, reflective finishes.

- Availability of all types of light supply.

Lamp placement and access methods

The technical documentation included in the lighting project for industrial premises and industrial buildings describes the standards for the height of lamps and spotlights. These characteristics are due to ensuring safety, efficiency and ease of maintenance:

- access to devices must be provided unhindered, so they are placed at a height of no more than 5 meters;

- in rooms with close proximity to thin-bearing walls - up to 2.1 m;

- on top of crane decks – 1.8 m;

- above the platform – 2.2 m;

- they must be mounted on special supports and suspended on fixed cables;

- installation at ground level and below is allowed;

- It is prohibited to install floodlights at a distance of less than a meter from roads, near fire shields, or on sidewalks;

- production areas, warehouses, overpasses can be connected to the internal network of an industrial facility;

- The security system is on a separate branch.

Hanging lamps should not fall more than 1.5 m. Overhangs are used to facilitate repair work.

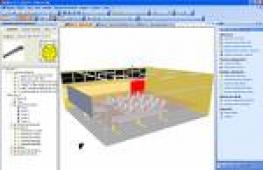

The quality of light output depends on a well-designed project. To do this, specialists use computer programs that help make calculations as accurate as possible:

- Dialux.

- Calculux.

- NanoCAD Electro.

- AutoCAD.

- ZWCAD.

- Compass.

- ES/EV power supply.

To obtain the highest possible performance, choose certified products.

Choosing software

The design of outdoor lighting for industrial enterprises, as well as networks in indoor spaces, is carried out using effective software. The ZWSOFT company sells professional products for designers, engineers and specialists in other professions. The flagship solution for implementing the most complex tasks is software, released in three versions:

- Standard;

- Classic;

- Professional.

Versions of this software are available with paid and free upgrade options, so the price should be checked with the manager. In general, the purchase is available for any budget - owners of large businesses and for personal use. This is an analogue of the well-known ACAD from Autodesk, which has similar functionality, but is less expensive. To carry out calculations for laying and installing electrical networks, let’s consider its capabilities:

- . The basis for three-dimensional modeling of the project is . This program is used for the development of three-dimensional graphics, including the creation of scenes and objects in it, visualization (rendering) and processing/editing with a large arsenal of tools. Using the CADprofi application, it is possible to design electrical networks for both civil and industrial purposes. CADprofi also interacts with calculation programs, allowing automatic placement of luminaires in accordance with the calculation results.

- The add-on is also used together with the main software – ZWCAD 2018 Pro. It is used to design power lines with voltages of 10 and 0.4 kV. To get started, you need to specify certain supports on the drawing to create a specification. The advantages include storing standard projects in the cloud, the presence of a local database for offline work, effective documentation in two languages, and no platform fees.

High-quality software is the way to create accurate and competent projects. Make the most of the presented products.

A production workshop, a warehouse, a conveyor - none of these objects can operate without lighting, which in this context is usually called industrial. Lamps of various types increase productivity, reduce personnel fatigue and ensure safety of the work process. Accordingly, increased requirements for reliability and functionality are placed on the design of lighting for industrial buildings and indoor workplaces.

Having trouble choosing lamps?

We will prepare a full calculation of the cost, necessary equipment and 3D visualization for lighting your facility. It's FREE - even before purchasing and concluding a contract, you will be able to evaluate:

“How much will it cost?”, “What will it look like?”, “How long will the meter run?”.

Types of industrial lighting

In industrial production, such types of lighting as natural, artificial and emergency are used. Let's take a closer look at each of them.

Daylight

It means the sun, the rays of which fall directly or reflected onto the illuminated object. There are several types of natural lighting in a building: top, side and combined. In the first case, light enters the room through openings in the ceilings. When applied from the side, it penetrates inside through openings in the walls. Both options combine combined lighting.

Artificial lighting

The need for it in production arose due to the inconsistency of the natural source - the sun. Working and duty (the second is used during non-working hours) provides visibility at work sites. For this purpose, luminaires with fluorescent, high-pressure gas-discharge lamps or LED sources are installed in buildings.

Emergency lighting

It is used in emergency situations and is divided into two types: for evacuation and for safety. The first provides the proper conditions for the prompt evacuation of people from the building and is represented by devices with inscriptions and signs. They are installed at exits or fire safety equipment locations. Lighting of industrial premises for safety purposes is required when turning off the main source leads to a dangerous situation: fire, poisoning, disruption of the technological process.

One of the types of artificial work lighting is LED. Industrial LED lamps are economical and ergonomic. They can be used in conditions of high humidity, at high and low temperatures, in dusty buildings. This is achieved due to the special housing design, which minimizes external influences on them and eliminates overheating. The last problem is solved by using radiators to remove heat.

LED elements are used in manufacturing plants and large buildings. They are capable of reducing electricity costs by 4-7 times compared to fluorescent and traditional sources. LED lamps are durable and do not require special care or maintenance. They have a high margin of safety, since the flask is made of polymer material, and therefore are suitable for difficult operating conditions. Even when broken, they do not release toxic substances, as is the case with fluorescent ones, so they do not pose a health threat to people present in the room.

Dome lamps

These suspended devices are designed for large industrial facilities (workshops, warehouse complexes, hangars) and other buildings with ceilings higher than 4 m. In addition to the dome design, they are characterized by a convenient fastening with a reflector rotation function. The configuration of the dome determines at what scattering angle the rays will propagate. Dome models have a dust- and moisture-proof housing (IP57 and higher), operate in a temperature range from -40 to +50 ° C and operate on average about 75 thousand hours.

Floodlights are installed not indoors, but also outside. They create a stream of rays and shape its transmission at a certain angle, depending on the design features of the housing, installed lenses and reflectors. Optical solutions that produce a beam of light at an angle of 15, 30, 45, 60 or 90° are common.

Ceiling lamps

Ceiling lamps are attached directly to the ceiling and create diffused rather than directed light, evenly illuminating the entire workshop, warehouse or other building. They can be built-in or overhead. Ceiling lamps are easy to maintain, economical and are also used for emergency lighting.

Individual lighting

It is used to highlight the work area of employees as much as possible, focus attention on details, or ensure compliance with safety regulations. It makes sense to equip the operator’s position on a conveyor belt or behind a machine. LED spotlights with a bright directional beam that hits the workplace of one or two or three workers would be appropriate here.

Lighting of workshops and warehouses

To solve this problem, LED solutions are widely used. They have proven themselves in the industrial sector for a number of reasons.

- Demonstrate cost effectiveness. They are 4-7 times more economical than halogen and fluorescent analogues and do not require regular replacement of starters.

- They last at least 50,000 hours. In practice, this figure reaches 75,000 and even 100,000 hours, which corresponds to 4-8 years of continuous operation.

- They pay for themselves within 6-12 months. This takes into account their service life, energy efficiency and it is assumed that they will be on 24 hours a day.

- They produce a luminous flux with different characteristics. Depending on the needs of production, the optimal values of the spectrum, power, and directivity are selected.

- Practical and reliable. Not only the service life of LED elements plays a role, but also the strength of the structure. They are not fragile, are not afraid of vibration and weigh little. They are not afraid of frequent switching on and off, dusty and humid rooms.

If a workshop, warehouse or other building has an elongated shape, it is reasonable to install linear ceiling devices in it. Dome solutions are suitable for organizing local light flux. If natural light enters the production room, the operation of the artificial source must adapt to it. This problem is solved by manually turning on and off lighting fixtures or using sensors and timers that operate automatically throughout the entire area or in individual sectors.

The influence of industrial lighting on human performance

Artificial light affects biological processes in the human body. It determines the visibility of objects in the workplace and affects the emotional state, endocrine and immune systems, metabolic rate and other vital processes. Natural light from the sun is a priority for the human body. In order for artificial analogues to replace it, the spectral compositions of the radiation must match. Otherwise, visual discomfort leads to the following consequences:

- Fatigue

- Decreased concentration

- The appearance of a headache

- Difficulty recognizing objects

Requirements and standards for lighting of industrial premises

Industrial structures are designed taking into account approved standards. Current standards make it possible to organize comfortable and safe workplaces. Requirements and standards are listed in the set of rules SP52.13330.2011 (formerly SNiP 23-05-95) “Natural and artificial lighting”. Engineers are also guided by SP 2.2.1.1312-03 “Hygienic requirements for the design of newly built and reconstructed industrial enterprises”, GOST 15597-82 “Lamps for industrial buildings. General technical conditions" and industry standards. Here is a brief statement of the basic design rules set out in these standards.

- The level of illumination in an industrial workshop or other structure corresponds to the type of work that is performed in it.

- The brightness is the same throughout the entire room. This is achieved by painting walls and ceilings in light shades.

- The lamps used have spectral characteristics that ensure correct color rendering.

- There are no objects with pronounced reflective surfaces in a person’s field of vision. This avoids direct and reflected glare and thus eliminates the possibility of glare.

- The room is evenly illuminated throughout work shifts.

- The possibility of sharp and dynamic shadows appearing in workplaces, which lead to an increase in injuries, is eliminated.

- Lamps, wires, switchboards, transformers are located in places that are safe for others.

Calculation of industrial premises lighting

Ergonomically correct lighting design creates comfortable and safe working conditions. When choosing lighting sources for a workshop, it is customary to rely on three evaluation criteria:

- The amount of luminous flux. Based on this parameter, the illumination required for a building or a separate sector is calculated and the number of sources to provide it is determined. This takes into account the type and purpose of the room, the area and height of the ceilings, and takes into account building rules and regulations, including industry ones.

- Colorful temperature. Determines the intensity of light radiation and its color - from warm yellow to cool white.

- Terms of Use. Here it is important to take into account the average temperature in the production room, the level of humidity, dust, vibration and other factors.

According to standards, if workers do not perform visual tasks, the brightness is 150 lm per 1 m2. If average visual load is assumed, this figure increases to 500 lm per 1 m2. In those rooms where they work with parts with a diameter of up to 10 mm, the luminous flux level is at least 1,000 lm per 1 m2. To obtain a luminous flux of 400-450 lm, you will need a 40 W halogen lamp, an 8 W fluorescent lamp or a 4 W LED lamp.

In the workplace, the color temperature is brought closer to the parameters of natural light. This is from 4,000 to 4,5000 K. If regular reading of documentation is expected, the color temperature is increased towards cool white, but not more than 6,000 K.

The power of the luminous flux is influenced by the installation features of the device (the higher it is located, the fewer lumens it produces), the presence or absence of a diffuser, and the degree of transparency of the glass. When choosing a specific light source, it is also customary to focus on the stability of the luminous flux, the efficiency of the selected product, its electrical parameters and safety requirements.

conclusions

Management companies and business owners in Moscow and beyond are increasingly using LED solutions for production and other facilities. LED light sources have declared themselves to be economical, durable, easy to maintain, comfortable for vision and safe from the point of view of constant exposure to the human body.

INTRODUCTION

Electric lighting plays a huge role in human life. Its significance is determined by the fact that with the correct implementation of lighting installations (OU), electric lighting (EL) helps to increase labor productivity, improve the quality of products, reduce the number of accidents and injuries, and reduce worker fatigue; provides significant performance and creates normal aesthetic, physiological and psychological effects on humans.

The correctness of the design of an op-amp is regulated by a variety of guidelines and regulatory documentation.

A complex criterion that evaluates the efficiency of a lighting installation is the annual levelized costs, which take into account initial costs and operating costs, as well as energy consumption, which is often considered as an independent indicator.

Due to the fact that electricity consumption for lighting is significant and amounts to 11 ... 14% of all electricity consumed in the country. And saving energy resources is a pressing problem. The use of energy-efficient op-amps that ensure minimal electricity consumption is the most important task.

The purpose of designing a lighting installation is to create a lighting environment that would ensure the lighting efficiency of lighting, taking into account the requirements of visual physiology, occupational health, and safety with minimal energy consumption and the cost of material and labor resources for the acquisition, installation and operation of the OU.

These goals are achievable by performing multivariate lighting calculations and choosing the most economical one, taking into account the requirements of current regulatory materials for the design, installation and operation of the OS.

This tutorial provides materials on designing the lighting and electrical parts of electric lighting. Lighting methods for calculating lighting are given - the luminous flux utilization coefficient method, the point calculation method using spatial and linear isoluxes. The calculation of an electrical lighting network is described - the selection of wire and cable cross-sections and the calculation of network protection.

The manual contains sufficient normative and reference materials for the design of an op-amp.

1. GENERAL INFORMATION ABOUT THE DESIGN OF LIGHTING INSTALLATIONS AND ARTIFICIAL LIGHTING

The design of lighting installations (OU) can be carried out in one or two stages.

For technically simple objects, as well as objects whose construction is carried out according to standard and re-used designs, the design of the OS is carried out in one stage - a working design (DP) is developed.

For large and complex objects, a two-stage design is carried out. At the first stage, a technical design (P) is carried out, at the second - working documentation (DD).

RP consists of lighting and electrical parts and working drawings.

In the lighting engineering part of the RP, the selection of illumination values and indicators of lighting quality, systems, types and methods of lighting, types of light sources (IS) and lighting devices (LD) is carried out, lighting calculations are performed, as a result of which the power and location of the OP are determined. The lighting part of the project ends with the preparation of a lighting sheet (Table A14).

In the electrical part of the switchgear, the op-amp power supply circuit and voltage are selected; the locations of group and main panels are determined and their types are selected; the route of the electrical network is determined; the choice of brand of wires and cables and methods of laying them is made; The lighting network is calculated, as a result of which the cross-section of wires and cables and the protection of the lighting network are determined.

In the RP, working drawings of the OU are developed, the composition and design rules of which are regulated by standards. Working projects should be focused on the implementation of electric lighting using industrial installation methods.

The scope of the RP for lighting of each facility includes a specification for lighting and electrical equipment, cables, wires, electrical installation products and other materials necessary for installation of the OU, and a statement of quantities for electrical installation work.

In a two-stage design, in the first stage P, the main fundamental issues in the lighting part of the op-amp are resolved. At the same time, the degree of depth and detail of elaboration of various issues can vary within significant limits.

At the next second stage, the RD is developed in the scope specified above for the RP, with the exception of the solution to the main fundamental provisions of the OS design identified in the first stage of the P.

The initial data for designing an OS are plans, characteristic dimensions of objects (buildings, premises, structures), their characteristics, information about the environment, etc., data about power sources.

The design of lighting installations can be done manually or automated by machine.

Lighting systems. Artificial lighting systems are determined by the way the lamps are placed. Based on the methods of placing lamps in rooms, a distinction is made between general and combined lighting systems.

The general lighting system is designed to illuminate the entire room and work surfaces. General lighting can be uniform and localized. General lighting lamps are located in the upper zone of the room and are attached to the building foundations directly to the ceiling, on trusses, on walls, columns or on technological production equipment, on cables, etc.

With general uniform lighting, uniform illumination is created over the entire area of the room. Lighting with uniform placement of lamps is used in industrial premises in which technological equipment is located evenly over the entire area with the same visual work conditions or in public or administrative premises.

General localized lighting is provided in rooms in which work is carried out in different areas that require different illumination, or when workplaces in the room are concentrated in groups and it is necessary to create certain directions of the light flux.

The advantages of localized lighting over general uniform lighting include reducing the power of lighting installations, the ability to create the required direction of the luminous flux, and avoiding shadows from production equipment and the workers themselves in the workplace.

Along with the general lighting system, local lighting can be used in the premises. Local lighting is provided at workplaces (machines, layouts, tables, marking tiles, etc.) and is intended to increase the illumination of workplaces.

The installation of only local lighting in premises is prohibited by standards. Local repair lighting is carried out with portable lamps, which are connected through a step-down transformer at a safe voltage of 12, 24, 42 V, depending on the category of the room in relation to the safety of operating personnel.

Local and general lighting, used together, form a combined lighting system. It is used in rooms with precise visual work that requires high illumination. With such a system, local lighting lamps provide illumination only for workplaces, and general lighting lamps provide illumination for the entire room, workplaces and mainly passages and driveways.

The combined lighting system reduces the installed power of light sources (IS) and energy consumption, since local lighting lamps are turned on only while work is being performed directly at the workplace.

The choice of one or another lighting system is determined mainly by the placement of equipment and, accordingly, the location of workplaces, the technology of the work performed, and economic considerations.

One of the main indicators characterizing the feasibility of using a general or combined lighting system is the density of workplaces in the room (m 2 /person). In table 1.1 in accordance with the recommended lighting systems for various categories of visual work, depending on the density of workplaces, and possible energy savings are given.

Table 1.1 Recommended areas of application of general and combined lighting systems

Types of lighting

In accordance with the rules, artificial lighting is divided into working, emergency, security and duty. Emergency lighting can be safety or evacuation lighting.

Work lighting is lighting that provides standardized lighting conditions (illumination, lighting quality) indoors and in places where work is carried out outside buildings.

Working lighting is provided for all areas of buildings, as well as areas of open spaces intended for work, the passage of people and traffic. For rooms with zones with different natural lighting conditions and different operating modes, separate lighting control for such zones should be provided.